OUR STORY

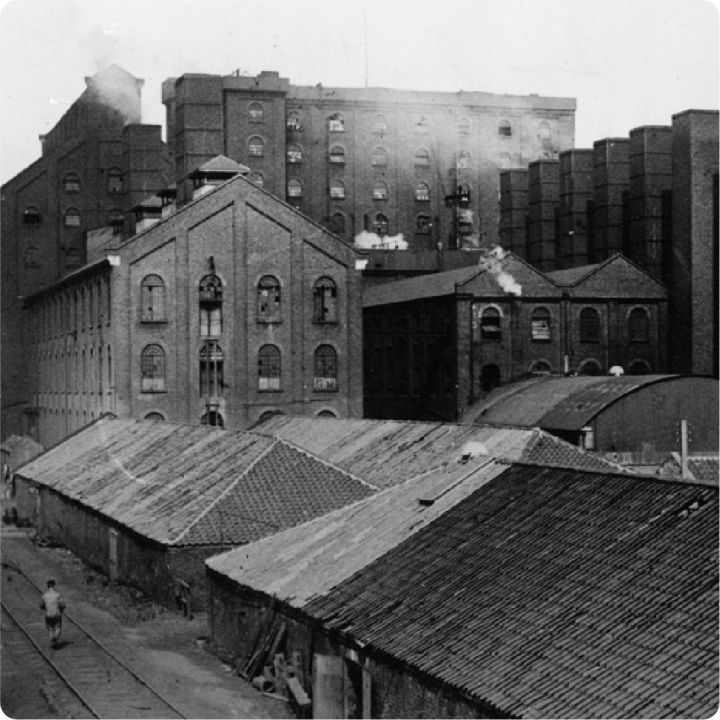

We have been refining cane sugar in east London since 1878, and our roots run deep.

Sustainably Refined

From the raw sugarcane through our whole supply chain, we are on a journey to refine and transform our business to be the most ethical and sustainable cane sugar refiner in the world.

We believe that when sustainably farmed, milled and refined, cane sugar has a pivotal role in regenerative agriculture and supplying renewable energy, prospering diverse communities and bringing joy to food and drink for all.

Farmed

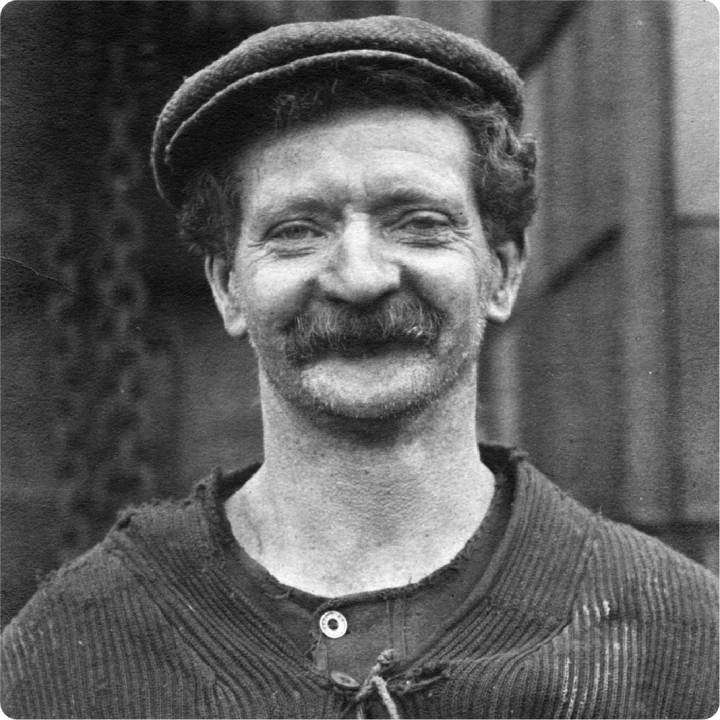

Our sugar starts with farmers who grow sugarcane. Cane farmers can be smallholders, medium or large estate farmers; farms can be independently owned or owned by the sugar mills themselves. Sugarcane is increasingly harvested mechanically, although some of it is still harvested by hand. In both cases, the cane stalk is cut close to the ground and the leaves are removed. The harvested cane is then transported to the sugar mill.

Milling

The first stage of processing is the mill. Mills are located close to the farms so that the cane is fresh when it arrives. This maximises the content and quality of the sugar that can be extracted from the cane. Milling involves squeezing the sweet juice from the sugarcane, and this is used to make sugar. The fibre that is left over from the milling process is called bagasse. Most cane mills use the bagasse as a fuel source to power the mill. Generally, the bagasse produced during the crop generates all the fuel needed for the sugar mill, with some to spare, so it is often used to provide green electricity for the local community as well.

Transported

A range of transport types including lorries, rail and barges transport the raw sugar from the mill to the port of export. Raw sugar is then loaded on to bulk ocean-going ships for its journey to Thames refinery in London. Around 20 vessels a year arrive at our jetty in London, carrying between 5,000 and 45,000 tonnes of raw sugar. The journey takes from 2 to 8 weeks depending on which supplying country the raw sugar is being shipped from.

Packed

Our Thames Refinery receives raw sugar from our ASR Group mills such as Belize Sugar Industries (BSI) as well as many third party mills. In the refining process, large quantities of raw sugar have impurities removed from them and are made into a wide range of brown and white sugars, as well as syrups and treacles. Products are packed and delivered to retail and food service customers as well as food and drink manufacturers.

Our products

At Tate & Lyle Sugars, we have been refining cane sugar on the banks of the Thames in East London since 1878. Since then, customer requirements have grown and we’ve developed our range of Tate&Lyle ® products tailored to the different needs of our customers. Take a look at our range and how you can use them!